International Business Correspondent

BBC

BBCListen to Theo reading this article

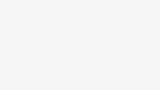

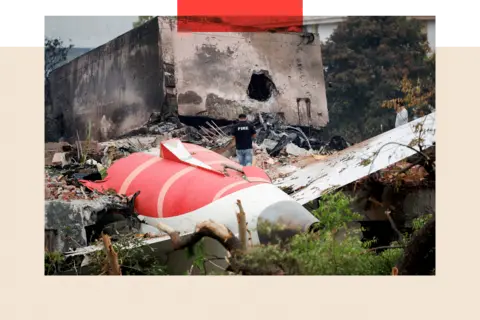

The Air India tragedy, in which at least 270 people died, involved one of Boeing’s most innovative and popular planes. Until now, it was considered one of its safest too.

We still do not know why flight 171 crashed just 30 seconds after take-off. Investigators have now recovered flight recorder data and are working hard to find out. But the incident has drawn attention to the aircraft involved: the 787 Dreamliner, the first of a modern generation of radical, fuel-efficient planes.

Prior to the accident, the 787 had operated for nearly a decade and a half without any major accidents and without a single fatality. During that period, according to Boeing, it carried more than a billion passengers. There are currently more than 1,100 in service worldwide.

However, it has also suffered from a series of quality control problems.

Whistleblowers who worked on the aircraft have raised numerous concerns about production standards. Some have claimed that potentially dangerously flawed aircraft have been allowed into service – allegations the company has consistently denied.

The Sonic Cruiser and the 9/11 effect

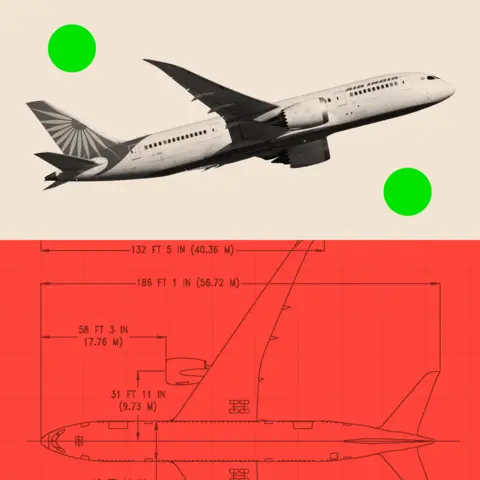

It was on a chilly December morning in 2009 that a brand-new aircraft edged out onto the runway at Paine Field airport near Seattle and, as a cheering crowd looked on, accelerated into a cloudy sky.

The flight was the culmination of years of development and billions of dollars worth of investment.

Getty Images

Getty ImagesThe 787 was conceived in the early 2000s, at a time of rising oil prices, when the increasing cost of fuel had become a major preoccupation for airlines. Boeing decided to build a long-haul plane for them that would set new standards in efficiency.

“In the late 1990s, Boeing was working on a design called the Sonic Cruiser,” explains aviation historian Shea Oakley.

This was firstly conceived as a plane that would use advanced materials and the latest technology to carry up to 250 passengers at just under the speed of sound. The initial emphasis was on speed and cutting journey times, rather than fuel economy.

“But then the effects of 9/11 hit the world airline industry quite hard,” says Mr Oakley.

“The airlines told Boeing what they really needed was the most fuel-efficient, economical long-range jetliner ever produced. They now wanted an aeroplane with a similar capacity to the Sonic Cruiser, minus the high speed.”

Boeing abandoned its initial concept, and began work on what became the 787. In doing so, it helped create a new business model for airlines.

Instead of using giant planes to transport huge numbers of people between “hub” airports, before placing them on connecting flights to other destinations, they could now fly smaller aircraft on less crowded direct routes between smaller cities which would previously have been unviable.

Airbus’s superjumbo vs Boeing’s fuel efficiency

At the time Boeing’s great rival, the European giant Airbus, was taking precisely the opposite approach. It was developing the gargantuan A380 superjumbo – a machine tailor-made for carrying as many passengers as possible on busy routes between the world’s biggest and busiest airports.

In hindsight, Boeing’s approach was wiser. The fuel-thirsty A380 went out of production in 2021, after only 251 had been built.

“Airbus thought the future was giant hubs where people would always want to change planes in Frankfurt or Heathrow or Narita,” explains aviation analyst Richard Aboulafia, who is a managing director at AeroDynamic Advisory.

“Boeing said ‘no, people want to fly point to point’. And Boeing was extremely right.”

Getty Images

Getty ImagesThe 787 was a truly radical aircraft. It was the first commercial plane to be built primarily of composites such as carbon fibre, rather than aluminium, in order to reduce weight. It had advanced aerodynamics to reduce drag.

It also used highly efficient modern engines from General Electric and Rolls Royce, and it replaced many mechanical and pneumatic systems with lighter electrical ones.

All of this, Boeing said, would make it 20% more efficient than its predecessor, the Boeing 767. It was also significantly quieter, with a noise footprint (the area on the ground affected by significant noise from the aircraft) that the manufacturer said was up to 60% smaller.

Emergency landings and onboard fires

Not long after the aircraft entered service, however, there were serious problems. In January 2013, lithium-ion batteries caught fire aboard a 787 as it waited at a gate at Boston’s Logan International Airport.

A week later, overheating batteries forced another 787 to make an emergency landing during an internal flight in Japan.

The design was grounded worldwide for several months, while Boeing came up with a solution.

Getty Images

Getty ImagesSince then, day to day operations have been smoother, but production has been deeply problematic. Analysts say this may, in part, have been due to Boeing’s decision to set up a new assembly line for the 787 in North Charleston, South Carolina – more than 2000 miles from its Seattle heartlands.

This was done to take advantage of the region’s low rates of union membership, as well as generous support from the state.

“There were serious development issues,” says Mr Aboulafia. “Some notable production issues, related especially to the decision to create Boeing’s first ever production line outside of the Puget Sound area.”

Damaging whistleblower allegations

In 2019, Boeing discovered the first of a series of manufacturing defects that affected the way in which different parts of the aircraft fitted together. As more problems were found, the company widened its investigations – and uncovered further issues.

Deliveries were heavily disrupted, and halted altogether between May 2021 and July 2022, before being paused again the following year.

However, potentially the most damaging allegations about the 787 programme have come from the company’s own current and former employees.

Among the most prominent was the late John Barnett, a former quality control manager at the 787 factory in South Carolina. He claimed that pressure to produce planes as quickly as possible had seriously undermined safety.

AFP via Getty Images

AFP via Getty ImagesIn 2019, he told the BBC that workers at the plant had failed to follow strict procedures intended to track components through the factory, potentially allowing defective parts to go missing. In some cases, he said, workers had even deliberately fitted substandard parts from scrap bins to aircraft in order to avoid delays on the production line.

He also maintained that defective fixings were used to secure aircraft decks. Screwing them into place produced razor-sharp slivers of metal, which in some cases accumulated beneath the deck in areas containing large amounts of aircraft wiring.

His claims had previously been passed to the US regulator, the Federal Aviation Administration, which partially upheld them. After investigating, it concluded that at least 53 “non-conforming” parts had gone missing in the factory.

An audit by the FAA also confirmed that metal shavings were present beneath the floors of a number of aircraft.

Boeing said its board analysed the problem and decided it did not “present a safety of flight issue”, though the fixings were subsequently redesigned. The company later said it had “fully resolved the FAA’s findings regarding part traceability and implemented corrective actions to prevent recurrence”.

‘A matter of time before something big happens’

Mr Barnett remained concerned that aircraft that had already gone into service could be carrying hidden defects serious enough to cause a major accident. “I believe it’s just a matter of time before something big happens with a 787,” he told me in 2019. “I pray that I am wrong.”

In early 2024, Mr Barnett took his own life. At the time he had been giving evidence in a long-running whistleblower lawsuit against the company – which he maintained had victimised him as a result of his allegations. Boeing denied this.

Much of what he had alleged echoed previous claims by another former quality manager at the plant, Cynthia Kitchens.

In 2011, she had complained to regulators about substandard parts being deliberately removed from quarantine bins and fitted to aircraft, in an attempt to keep the production line moving.

Ms Kitchens, who left Boeing in 2016, also claimed employees had been told to overlook substandard work, and said defective wiring bundles, containing metallic shavings within their coatings, had been deliberately installed on planes – creating a risk of dangerous short-circuits.

Boeing has not responded to these specific allegations but says Ms Kitchens resigned in 2016 “after being informed that she was being placed on a performance improvement plan”. It says that she subsequently filed a lawsuit against Boeing, “alleging claims of discrimination and retaliation unrelated to any quality issues”, which was dismissed.

Getty Images

Getty ImagesMore recently, a third whistleblower made headlines when testifying before a senate committee last year.

Sam Salehpour, a current Boeing employee, told US lawmakers he had come forward because “the safety problems I have observed at Boeing, if not addressed could result in a catastrophic failure of a commercial aeroplane that would lead to the loss of hundreds of lives”.

The quality engineer said that while working on the 787 in late 2020, he had seen the company introduce shortcuts in assembly processes, in order to speed up production and delivery of the aircraft. These, he said, “had allowed potentially defective parts and defective installations in 787 fleets”.

He also noted that on the majority of aircraft he looked at, tiny gaps in the joints between sections of fuselage had not been properly rectified. This, he said, meant those joints would be prone to “premature fatigue failure over time” and created “extremely unsafe conditions for the aircraft” with “potentially catastrophic” consequences.

He suggested that more than 1,000 aircraft – the bulk of the 787 fleet – could be affected.

Boeing insists that “claims about the structural integrity of the 787 are inaccurate”. It says: “The issues raised have been subject to rigorous examination under US Federal Aviation Administration oversight. This analysis has validated that the aircraft will maintain its durability and service life over several decades, and these issues do not present any safety concerns.”

‘Serious problems would have shown up’

There is no question that Boeing has come under huge pressure in recent years over its corporate culture and production standards. In the wake of two fatal accidents involving its bestselling 737 Max, and a further serious incident last year, it has been repeatedly accused of putting the pursuit of profit over passenger safety.

It is a perception that chief executive Kelly Ortberg, who joined the company last year, has been working hard to overturn – overhauling its internal processes and working with regulators on a comprehensive safety and quality control plan.

But has the 787 already been compromised by past failures, that may have created ongoing safety risks?

Reuters

ReutersRichard Aboulafia believes not. “You know. It’s been 16 years of operations, 1,200 jets and over a billion passengers flown, but no crashes until now,” he says. “It’s a stellar safety record.”

He thinks that any major issues would already have become apparent.

“I really think production problems are more of a short-term concern,” he says. “For the past few years, there’s been far greater oversight of 787 production.

“For older planes, I think any serious problems would have shown up by now.”

The Air India plane that crashed in Ahmedabad was more than 11 years old, having first flown in 2013.

But the Foundation for Aviation Safety, a US organisation established by the former Boeing whistleblower Ed Pierson that has previously been highly critical of the company, says it did have concerns about 787s prior to the recent crash.

“Yes, it was a possible safety risk,” claims Mr Pierson. “We monitor incident reports, we monitor regulatory documents. Airworthiness directives come out that describe various issues, and it does make you wonder.”

Getty Images

Getty ImagesOne such issue, he argues, is water potentially leaking from washroom taps into electrical equipment bays. Last year, the FAA instructed airlines to carry out regular inspections, following reports that leaks were going undetected on certain 787 models.

However, he stresses that the cause of the recent tragedy is still unknown – and that it is vital the investigation moves forward quickly, so that any problems, whether they lie with the aircraft, the airline or elsewhere, can be resolved.

For the moment, however, the 787’s safety record remains strong.

“We don’t know at this point what caused the Air India crash,” says Scott Hamilton, managing director of aviation consulting firm Leeham Company.

“But based on what we do know about the plane, I would not hesitate to get on board a 787.”

Top image credit: Getty Images

BBC InDepth is the home on the website and app for the best analysis, with fresh perspectives that challenge assumptions and deep reporting on the biggest issues of the day. And we showcase thought-provoking content from across BBC Sounds and iPlayer too. You can send us your feedback on the InDepth section by clicking on the button below.

Source link

Unews World

Unews World